|

Materials - PREPARATIONS FOR TREATMENT OF ALLOYS ON THE BASIS

OF ALUMINIUM

THE DESCRIPTION

At present only high-quality castings meeting the physicotechnical

requirements of the consumer are demanded in the market. Any ineffective

production methods involve loss in quality of casting, provoking

various kinds of waste (porosity, nonmetallics, the inferior mechanical

properties, insufficient surface smoothness, etc.). Production of

competitive high-quality casting is impossible without application

of highly effective procedure on the basis of complex preparations.

In this connection a series of ecologically safe preparations of

different function for volume and a surface treatment of alloys

on the basis of aluminium, zinc and other alloys has been developed.

Complex treatment of alloys with tableted preparations together

with flux compositions is an effective element of procedure of decrease

of oxides and hydrogen content in melt, high-quality modifying of

non-ferrous melts and solving other problems.

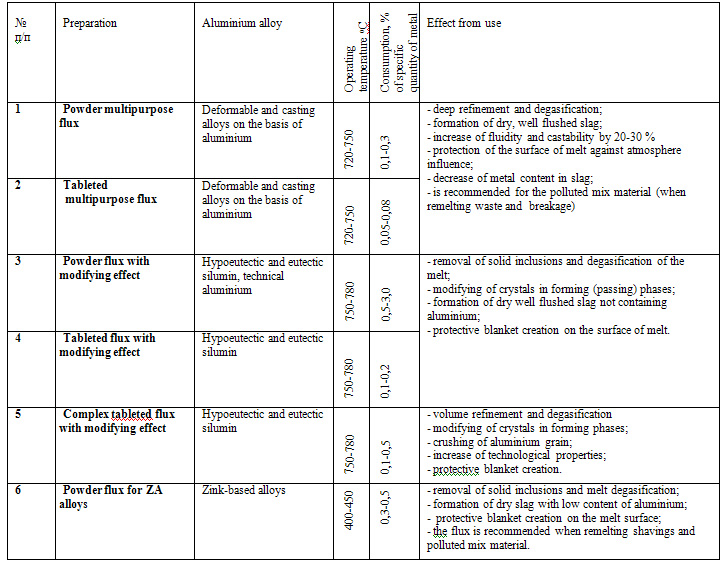

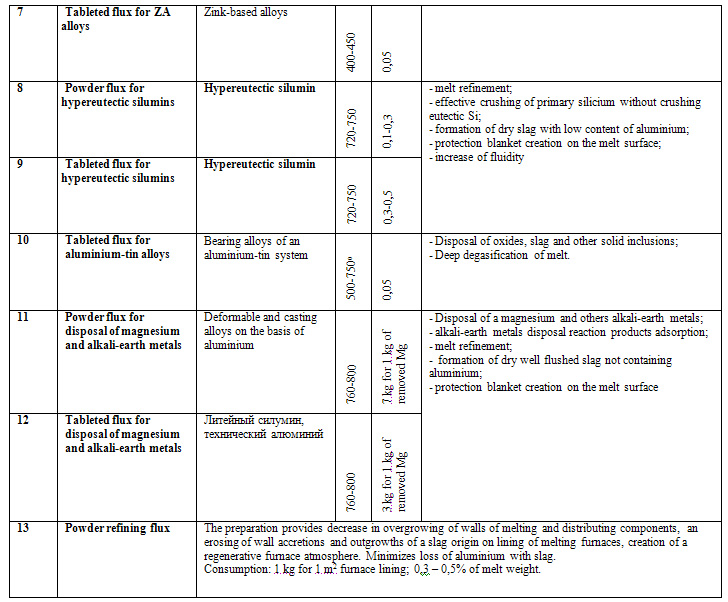

THE LIST OF PREPARATIONS FOR TREATMENT OF NON-FERROUS ALLOYS

THE APPLICATION

For achieving maximum refining and modifying effect complex melt

treatment by flux compositions and corresponding tableted preparations

is recommended. In cases their joint use is impossible or inexpedient

powder and tableted preparations may be used separately.

Usually the melt is brought to necessary temperature and rated

amount of powder flux is spread over the surface of melt and actively

mixed into it. Tablet is introduced into melt by an immersion bell.

The preparation is brought down to the bottom of the ladle and rotatory

movements with the bell are being performed while boiling of metal

(5-7 minutes) continues. After the treatment a pause of 3-10 minutes

is kept before slag is flushed.

ADVANTAGES OF USAGE

- high efficiency;

- improvement of a number of mechanical and technological properties

of the metal;

- cost-effectiveness at stable high quality, low consumption,

low cost etc.;

- affordability and simplicity of application;

- ecological safety;

- " substantial economy of metal (30kg/ton).

Packing: Tablets: twofold cardboard boxes with polyethylene

interlayer containing from 30 to 1000 pieces. Flux: plastic bags

0,5-2 kg each packed in cardboard box or paper bags 25 kg each on

pallets wrapped in film.

If you are interested in introduction of highly effective processes

of treatment of cast irons and non-ferrous melts collaborators of

our enterprise are ready to render consulting and technical support

including a business-trip onto your enterprise with a test batch

of necessary materials. This service is given at a no cost.

|