|

Materials - FILTER MEDIUMS

THE PURPOSE

Filter elements TU BY 590339385.001-2005 are designed for fine filtration

of melts of ferrous (grey, ductile and high-duty cast iron, high-carbon

and manganese steels) and non-ferrous materials when casting in

disposable sand molds and chill.

The filter base is hard grid-type structure 1.2 mm thick, size of

filter cells: 1.5x1.5 mm; 2.0x2.0 mm (1.0x1.0 mm for aluminum alloys)

and heat resistance up to 16800C.

THE APPLICATION

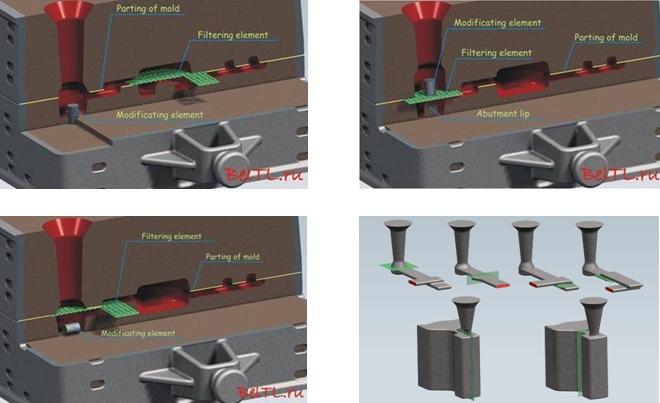

The filter elements may me placed as straight below the down sprue,

as inside the gating system. The size of the applied filter by its

contour should be 10 to 15 mm more than its working surface (surface

contacting the metal) to ensure leak-free fixation.

For large size filters support, abutment elements may be provided

in lower part of the pouring basin of the gating system.

ADVANTAGES OF USAGE

- no alteration of the gating system is needed;

- low price (compared to ceramics);

- sharp decrease in casting waste due to nonmetallic inclusions

and gases presence;

- decrease in specific quantity of metal in the gating system, as

there are no elements blocking metal flow and slag traps in the

gating;

- casting composition mechanical properties improvement.

If you are interested in introduction of highly effective processes

of treatment of cast irons and non-ferrous melts collaborators of

our enterprise are ready to render consulting and technical support

including a business-trip onto your enterprise with a test batch

of necessary materials. This service is given at a no cost.

ODO "Beltechnolit" is looking for regional representatives

in CIS, Europe, Asia, etc., welcomes other forms of collaboration

in the scope of foundry production distribution.

|