|

Materials - ADIABATIC INSET

THE

PURPOSE THE

PURPOSE

Adiabatic insets TU BY 590339385.005-2008 are designed to be used

for producing large-size (bulky) casts of all sorts of steel, cast

iron and non-ferrous materials with casting temperature up to 16500C

for riser heat insulation to increase solidification time in the

feeding boss and considerably rise its efficiecy. Using feed systems

with adiabatic insets has the aim of increasing in-spec casting

output (by 10-15%) because of decrease of specific quantity of metal

of risers (up to 30%) and decreasing power inputs and elimination

of cast waste due to shrinkage defects.

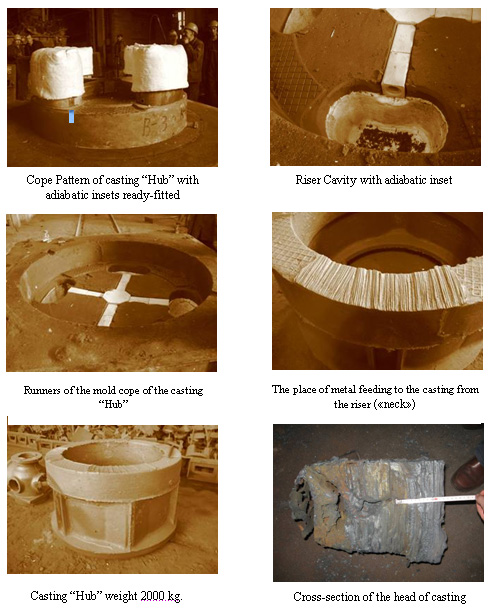

Installation of adiabatic insets: on riser pattern in the cope before

molding, upper casting flask riser cavity dressing after molding.

Flexibility and elasticity of the inset material allow dressing

feed bosses of any configuration.

Main parameters and characteristics.

1.Adiabatic insets are produced of mullite-silicious fiber based

material as compressed fibrous voluminous fabric, formed (compressed)

in a mechanical way and cut out in curves of necessary configuration.

By agreement with the customer the inset may be sewn (fastened)

and its working surface applied refractory dye to.

2. The form of release of products:

- In a form of cut-out fabric (under the sketches coordinated with

the customer);

- The sewed (fastened) voluminous adiabatic riser (under the drawings

coordinated with the customer).

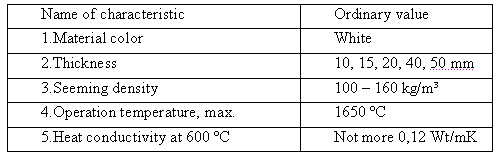

3. Physicotechnical characteristics of adiabatic insets are resulted

in the table:

Example of an use. Casting "Hub". Brand of steel

- 25, weight of the Casting - 2000 kg. Number of risers for 1 cast

- 4. The use of adiabatic insets increased recovery by 15% by the

risers specific quantity of metal reduction of 440 kg.

|